Digital Transformation in Manufacturing: How Web Tools Are Replacing Old Software

Have you ever thought about what is holding back modern manufacturing from reaching its full potential?

There might be many answers to this, but one thing is clear – it’s the use of outdated software.

Today, slow systems are counterproductive. Consider a mid-sized automotive parts manufacturer that used an old, on-premise ERP system. They had to update the inventory manually, reporting was too late, and during updates, the system crashed frequently.

Shifting to a cloud-based inventory system was the best decision they made. They got real-time visibility, reporting became automated, and production delays were reduced.

Digital transformation is reshaping the way factories operate. It is powered by website design that reflects your brand, AI-driven tools like chatbots, and other innovations. The latest technology is replacing old software. Let us understand how?

In this article, we will explore the challenges with old software, the role of web tools in digital transformation, and areas where web tools are replacing old software.

Challenges With Old Software in Manufacturing

Many manufacturers are dependent on legacy software systems for on-premise ERP suites and custom-built inventory trackers. These tools may have worked best in the past, but at present, they are not that efficient.

Here’s how:

- High maintenance cost: To install, update, or troubleshoot older software, there is a need for an IT team. Also, the hardware investment costs are usually huge.

- Lack of real-time data access: Most legacy tools don’t have real-time collaboration or cloud access. This leads to delays in decision-making.

- Limited integration: Integrating older systems with modern IoT devices, analytics dashboards, LLM frameworks, or AI-based tools requires workarounds and expensive middleware.

- User experience and training: Legacy tools do not have an intuitive design. Therefore, it makes onboarding a time-consuming process. In fact, just like a well-thought-out logo design can improve brand recognition, intuitive software design can improve user adoption and reduce training time.

- Security risks: Older software is not being updated now, so it might be vulnerable to cyber threats.

In the age where speed matters a lot, manufacturers cannot afford to be held back due to these reasons.

Role of Web Tools in Digital Transformation

A well-planned manufacturing website design, along with ERP-integrated web portals or customer portals, plays an important role in digital transformation. It enables automation, AI-driven insights, and cloud-based scalability.

Here’s why they matter:

- Accessibility: Web tools can be accessed from any device with a browser. This makes it easy for remote teams, factory supervisors, and others to stay connected and updated with recent data.

- Scalability: You don’t have to estimate the space or the resources you will need as your business grows. Cloud-based tools can scale as your business grows. There’s no need to reinstall or grow the infrastructure. This saves money and time.

- Interoperability: Many web apps offer APIs and support integrations with existing systems, sensors, and ERPs. This creates a connected manufacturing ecosystem.

- Automation and AI integration: Web tools help manufacturers embed AI and machine learning into their daily operations. The integration of AI voice cloning into training and operations is an example where realistic voices deliver instructions or simulate real-world scenarios.

Let us look at a real-life example to understand how web tools lead to digital transformation.

Case Study: How Sanmina Used Web Tools to Drive Global Digital Transformation

Company Overview:

Sanmina is a Fortune 500 global electronics manufacturer. It produces over 250 million products annually for more than 700 original equipment manufacturers (OEMs).

The Challenge

Sanmina operated more than 50 factories spread across 15 countries. Each of them had its own production systems that relied on traditional on-premise manufacturing execution systems. These systems were costly to maintain, difficult to scale, and dependent on local IT teams.

Due to such a setup, they couldn’t get real-time visibility of global production data. Executives couldn’t get a centralized view of operations, and the important decisions were delayed because there was no access to instant data.

The Solution

Sanmina decided to deploy a cloud-based MES platform that could be easily accessed through web browsers. It did not require complex installations. With this system in place, they began tracking data in real-time.

The Result

This transition brought a huge impact on Sanmina’s systems:

- They could get real-time visibility across all 50+ global plants.

- They did not require dedicated IT teams for maintenance or installations.

- They got automated operational alerts for any machine-related problems or lower production quantity.

- There was end-to-end supply chain transparency from raw materials to the final product.

With all these results, the operation became smarter, and the customers became happy. If you understand where web tools are replacing old software, then you can figure out where your system needs transformation.

Key Areas Where Web Tools Are Replacing Old Software

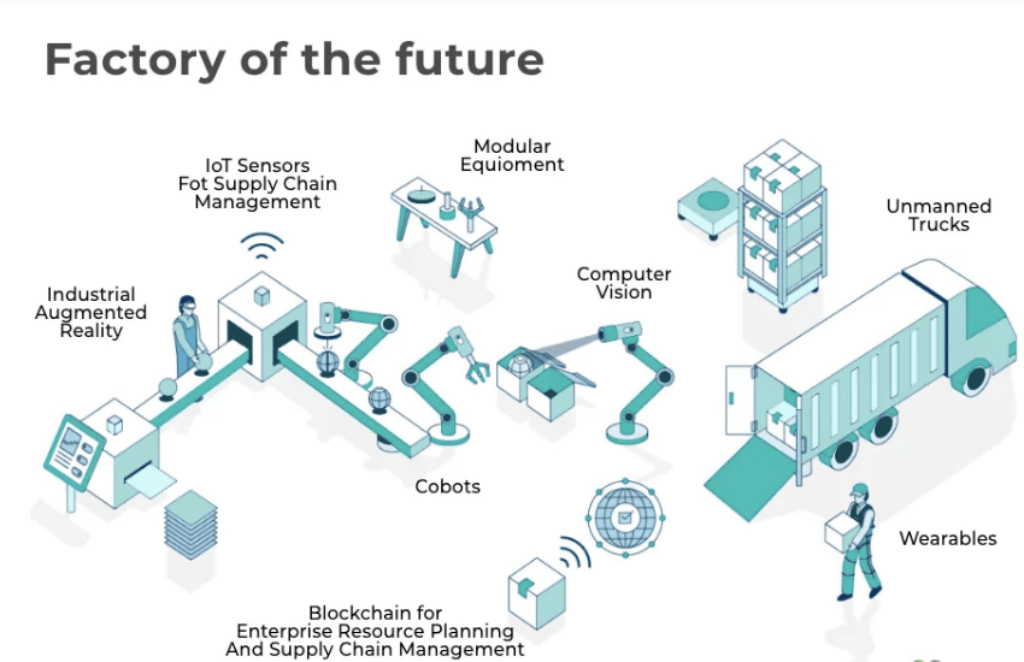

Web tools are transforming many traditional systems. Let us look at some of them:

- Inventory management and supply chain

Legacy inventory systems were on local servers and required manual data entry. This led to human error, blind spots, and delayed decisions.

Unlike this, cloud-based inventory platforms provide real-time visibility. Companies can instantly access stock information across multiple warehouses. The records will be updated automatically based on orders and sales.

If your business has better inventory visibility, then it reduces overstocking, lowers costs, and improves vendor communication.

- Production planning and scheduling

The scheduling tools that were used traditionally were unable to adapt to changes like machine breakdowns, late material arrivals, or urgent orders.

But modern production planning software helps managers to drag and drop tasks on a real-time schedule, monitor capacity by shift, and adjust workflows.

With this technology, the deadlines are not missed, machineries are used wisely, and products are delivered quickly to customers.

- Quality control and compliance

In older systems, quality control relied on paper checklists or standalone tools that were not integrated with other systems.

But modern tools help technicians to enter data through tabs, which can quickly sync it to the central dashboard.

This benefits businesses with faster problem detection, automatic audit logs, and increased product consistency.

- Maintenance and equipment monitoring

Traditionally, maintenance was done after a machine broke. But by using various modern techniques, we can now easily predict the health of a machine and know when a machine needs maintenance.

- Training and workforce enablement

Training used to mean group sessions, printed manuals, or basic videos. But with cloud-based learning platforms, you can create online courses and make them live on the platform.

Learners can learn at their own pace, and you can monitor progress, milestones, and challenges in real time.

- Collaboration and communication

In a traditional setup, internal communication used to happen through emails, on paper, or notice boards.

But now platforms like Slack, Microsoft Teams, or custom dashboards help teams stay updated with real-time changes instantly.

This leads to proper alignment with all the team members.

Technology is transforming the way things work in factories worldwide. With web tools, everything is simpler, faster, and more efficient.

It’s Time to Modernize Your Manufacturing

We have understood how digital transformation can give a competitive edge to your company. It can help with smart inventory management, proper production planning and scheduling, regular reporting on equipment, and effective team collaboration.

So, are you ready to transform your manufacturing operations?

We help businesses build custom and intuitive solutions. Contact us today, and we will help you assess your current systems and get personalized and transformative upgrades.